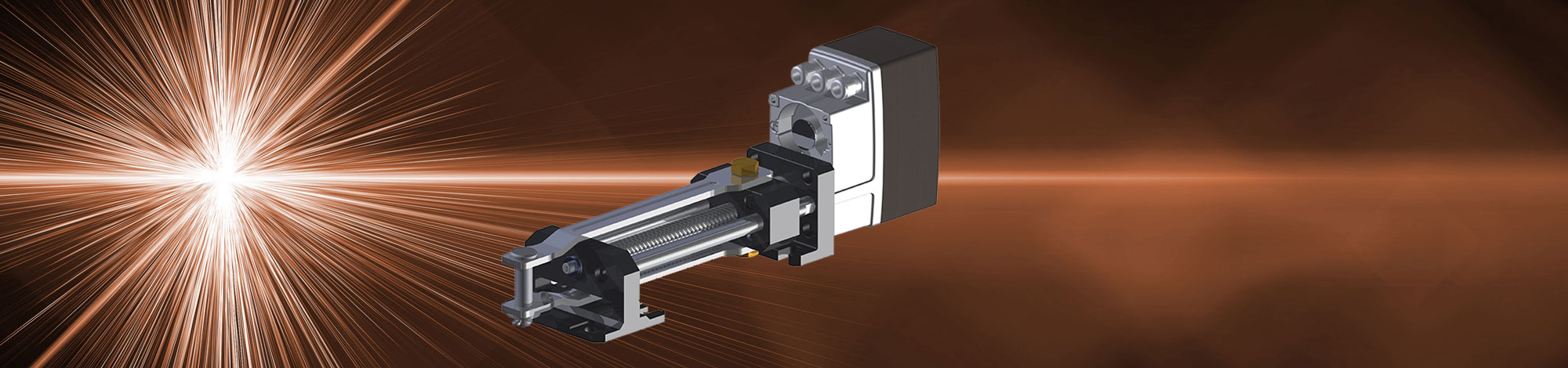

Linearis NA+ Ex 2/22

Electro-mechanical damper actuator for Ex-Zone 2 and 22

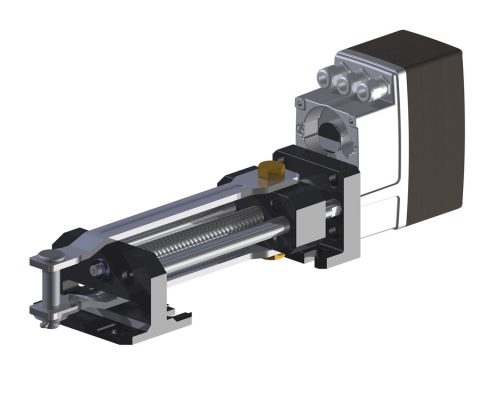

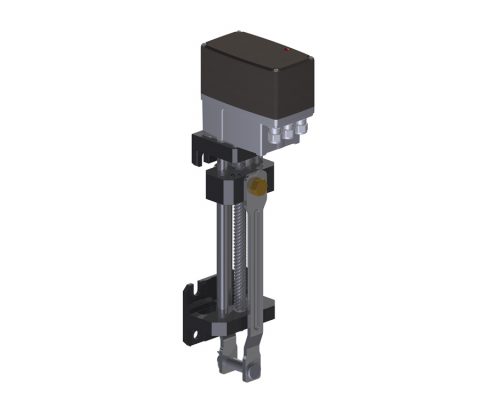

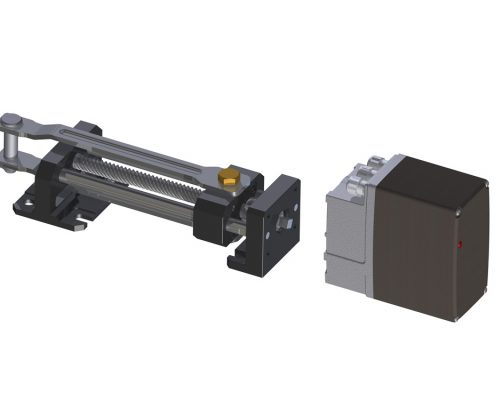

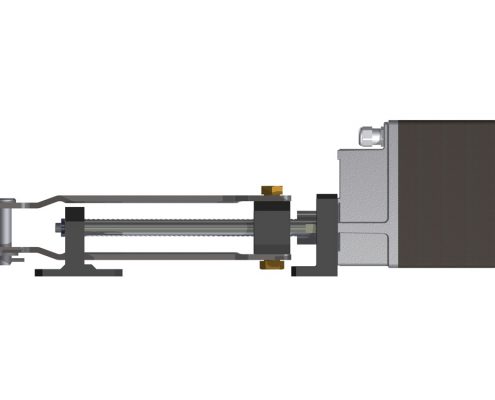

The Nano+ offers classic drive technology in a modern design. The classic drive system, consisting of a motor-gearbox combination and a switch-off system consisting of switching cams and microswitches, is still valid today. For this reason, the Nano+ series was completely redesigned on the basis of the Nano in 2014, since classical drive technology is not necessarily equivalent to “old technology”. All conceivable options have been taken into account in the new design and have been designed in such a way that they are always firmly in place and offer optimum operational safety thanks to an optimal covering of all voltage-carrying parts.

A stainless steel split spindle with a dryspin® spindle nut ensures reliable and maintenance-free operation. Due to the high lead, the required engine speed is significantly reduced in comparison to the classic design, so that the engines run much smoother and quieter. This considerably increases the service life of the motors. Instead of the commercially available castings, Linearis N+ uses anodized aluminum machined parts, which are significantly more robust at low weight. The Linearis has been developed by practitioners. Long holes in the brackets allow easy assembly even by only one mechanic. Dirt deposits are prevented by the spindle in the dry run so that large and expensive bellows designs are no longer required. The synchronous motors used in the drive head operate with a purely frequency-dependent positioning time and thus ensure precise control. The switching cams are supported by special planetary gear units required for the linear movement on the travel distance and allow an exact adjustment of the travel limit switches. A robust powder-coated housing reliably protects drive technology even in harsh industrial environments. Despite the compact dimensions of the drive head, the Linearis N+ allows all standard options, including emergency operation in case of power failure.

The Linearis lift unit is also designed to meet the requirements of the ATEX directives so that the combination of the linear unit and the zone 1 drive is a reliable unit.

The Linearis N+ is available in standard stroke lengths of 150 and 300 mm for actuators up to 5000 N.

Other forces up to 7000 N and other stroke lengths are also available on request.

Force

N

Actuating time

mm/s