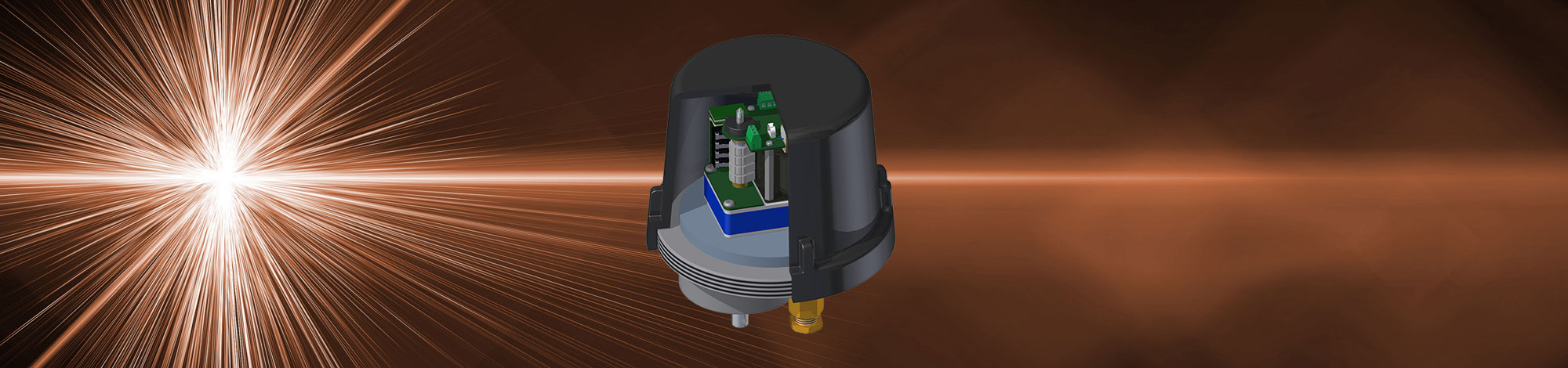

Nano + Ex 1

Electro-mechanical actuator for Ex-Zone 1

Classic drive technology in a rugged housing with compact dimensions. ARIS actuators of the series Nano+ Ex designed for industrial use in zone 1 areas. They are used for the actuation of regulating and shut-off devices, e.g. flaps, valves, ball valves, dosing pumps etc., and offer a high safety level. The classic drive technology of the Nano+ with synchronous or direct current motor allows a simple replacement of actuators in existing circuits and systems. The large number of mounting holes according to ISO 5211 and a change-over shaft system ensure a simple construction on all standard fittings without costly brackets. The drives of Zone 1 are characterized by a high level of intrinsic safety and operational safety.

Torque

5...120

Nm

Actuating time

0.8...210

sec/90°