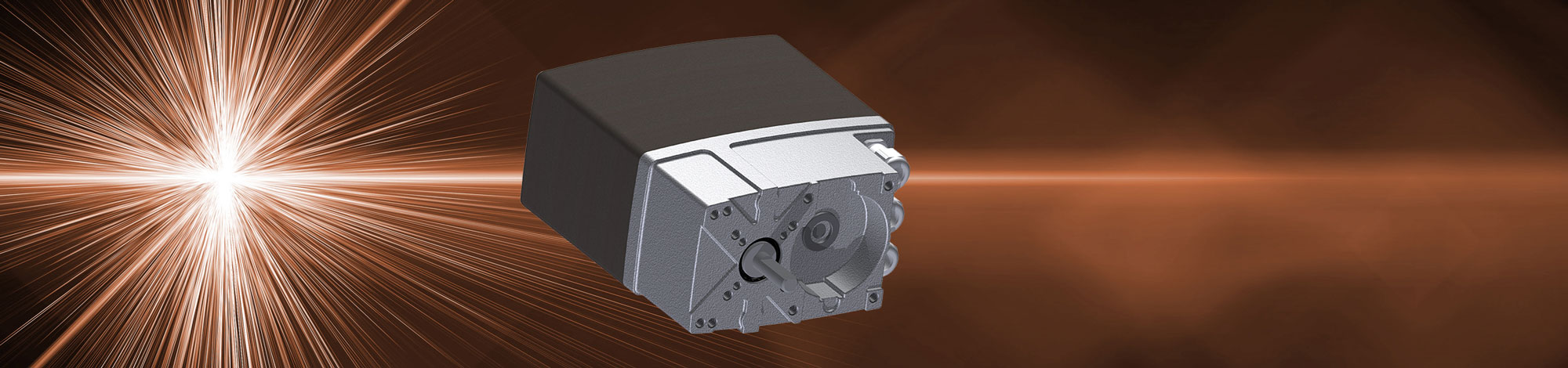

Tensor Ex 2/22

Fully electronic rotary drive for Ex-Zone 2 und 22

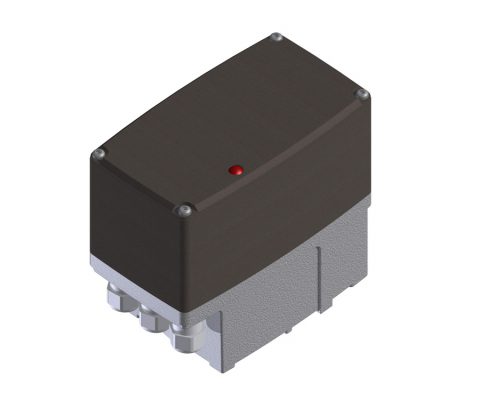

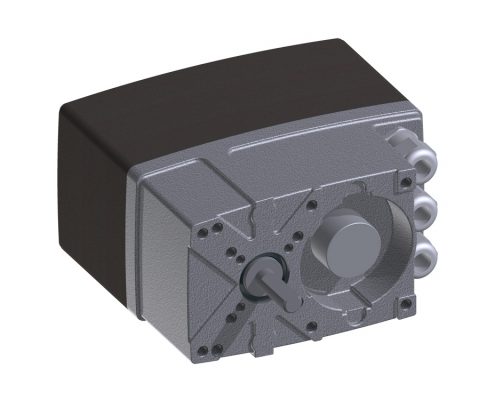

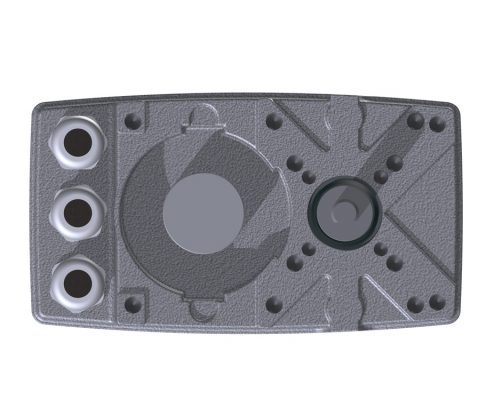

Advanced drive technology in a sturdy housing with compact dimensions. ARIS actuators of the series Tensor Ex are designed for industrial use in zones 2 and 22, which are potentially explosive, according to their marking. They are used for the actuation of regulating and shut-off devices, e.g. flaps, valves, ball valves, dosing pumps etc., and offer a high safety level. The robust, powder-coated housing and the metal hood of the drives ensure safe and reliable operation in zones 2 and 22. The wide range of mounting holes according to ISO 5211 and a change-over shaft system ensure simple assembly on all standard fittings without costly brackets. For the zones 2 and 22 no pressure-proof encapsulation is necessary so that the drive has significantly less weight than drives of the zone 1.

Torque

Nm

Actuating time

sec/90°