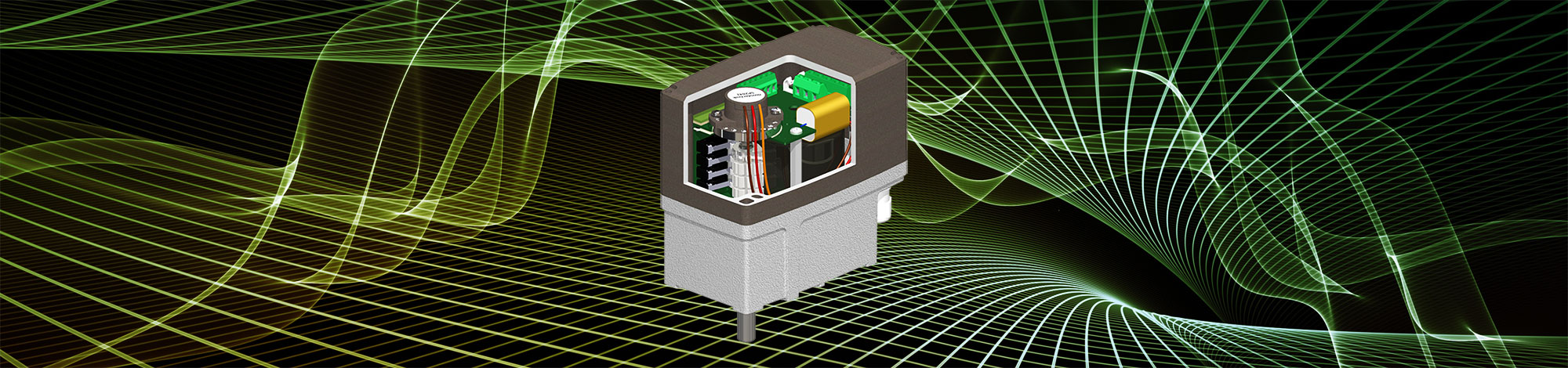

Nano+

Electro-mechanical part-turn actuator

The flexible allrounder, completely metal encapsuled with a wide accessory range and classic technology up to 500 Nm

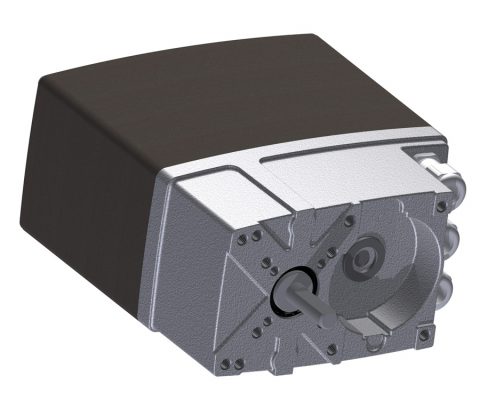

The Nano+ offers classic drive technology in a modern design. The classic drive system, consisting of a motor-gearbox combination and a switch-off system consisting of switching cams and microswitches, is still valid today. For this reason, the Nano+ series was completely redesigned on the basis of the Nano in 2014, since classical drive technology is not necessarily equivalent to “old technology”. All conceivable options have been taken into account in the new design and have been designed in such a way that they are always firmly in place and offer optimum operational safety thanks to an optimal covering of all voltage-carrying parts.

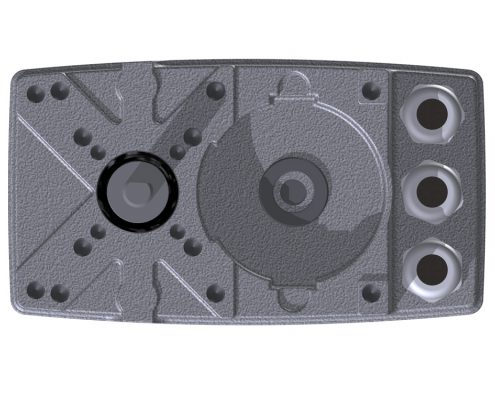

A height-adjustable and powder-coated aluminum hood in combination with the powder-coated basic housing also ensure a worry-free use even in the harshest industrial environment. In addition, fixable cams ensure a safe switch-off in the set position even in the case of strong vibrations. The height-adjustable metal hood allows a multitude of additional options ranging from multiturn applications to fast response times with high torque and fail-safe function for the DC variant.

Test institutes confirmed the suitability for the electronic circuit according to DIN EN 12067-2 and/or in potentially explosive areas of Zone 2 or 22. The allrounder Nano+ is available in voltages of 230 V, 115 V, 24 V AC or 24 V DC and offers an almost unrestricted application in all industrial applications.

Torque

Nm

Actuating time

sec/90°