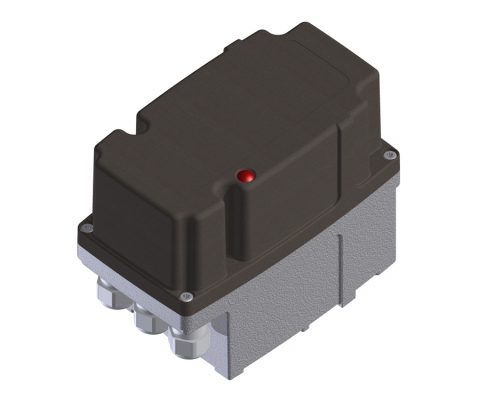

Tensor

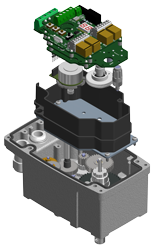

Fully electronic rotary drive

The precision drive with wide range power supply, wear-free absolute position detection and high control accuracy. Your entry to Industry 4.0

With the series Tensor ARIS offers an innovative generation of electronically controlled actuators. The Tensor is based on a low-backlash precision gear in combination with a brushless DC motor. The Tensor´s complete mechanical shut-off system has been replaced by a wear-free, non-contact position detection, which is based on the Hall effect. This sensor technology was developed many years ago for use in the automotive industry and has proved extremely robust, wide temperature range and high reliability.

Previously, with the classic actuators the user had to hold many actuators with different shutdown systems for different adjustment paths. Now the electronic system comfortably covers all control options with a single version. With the non-contact position sensing system it is practically wear-free and guarantees constant precision. Problems and long-term drift effects caused by switching hysteresis at potentiometers and switch point hysteresis at micro switches, are also a thing of the past. In total, the result for the user is a noticeably higher control accuracy for the entire drive, which also remains practically constant over the drive´s lifetime.

In addition to precise control, the electronic positioning system provides a significantly simpler and faster start-up by programming using buttons. A permanent torque monitoring protects actuator and valve reliably against overloading.

BLDC motors have Hall sensors according to their poles, with which the electronic controls the phase currents of the motor and realizes the electronic commutation. In addition, the motor management system monitors the line current itself. Malfunctions as a movement in the wrong direction, the wrong speed or overload condition are detected immediately and lead to shutdown of the drive. Since the motor is driven over a defined signal sequence, an undesired or even uncontrolled movement is excluded here.

The possibility of speed control combines the functions of multiple drives in a single device, thus reducing the investment costs. The multi-voltage power supply in connection with the adjustment range of a few degrees up to several revolutions significantly reduce the stock list and storage costs. The permanent control of the drive system, increases the operational reliability of the plant.

Torque

Nm

Actuating time

sec/90°