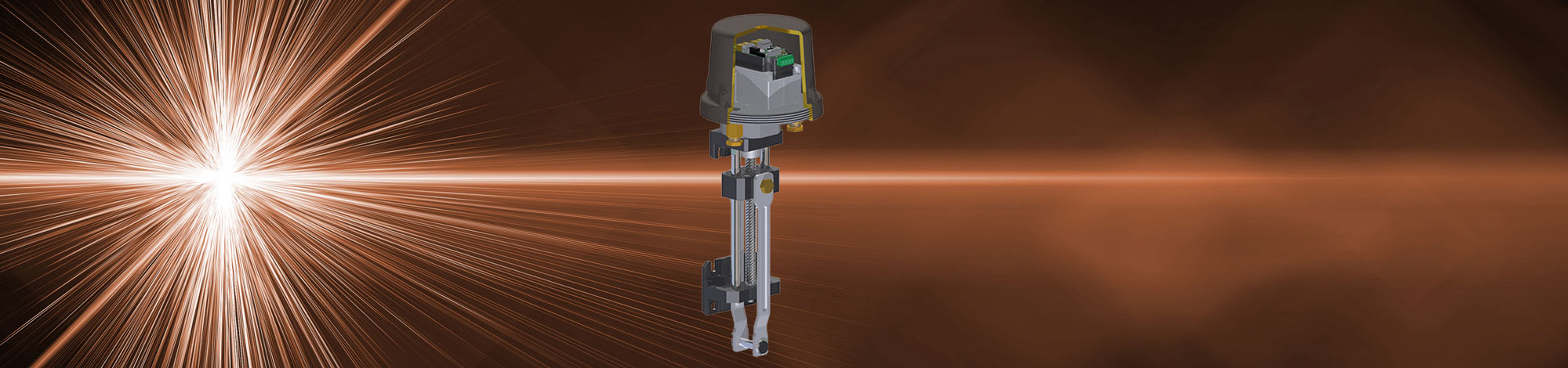

Linearis TE Ex 1

Fully electronic damper actuator for Ex-Zone 1

With the Tensor series, ARIS offers an innovative generation of electronically controlled actuators. The Tensor is based on a low-play precision gearbox in combination with a brushless DC motor. In the Tensor, the complete mechanical shut-off system was replaced by a wear-free and non-contact position detection based on the Hall effect. This sensor technology was developed years ago for use in the automotive industry and has proved itself through extreme robustness, wide temperature range and high reliability. ARIS actuators of the series Tensor Ex are designed for industrial use in zone 1 hazardous areas. They are used for the actuation of regulating and shut-off devices, e.g. flaps, valves, ball valves, dosing pumps etc., and offer a high safety level. The drives of Zone 1 are characterized by a high level of intrinsic and operational safety.

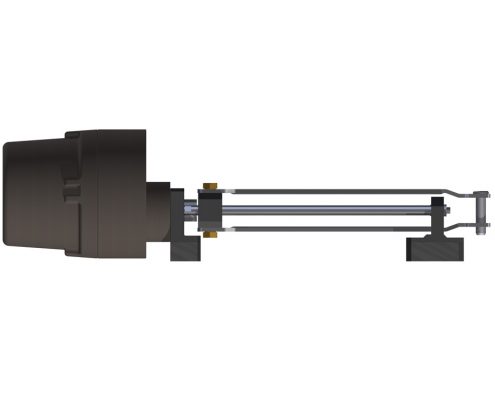

A stainless steel high-helix spindle with dryspin® spindle nut made of high-performance polymer ensures reliable and maintenance-free operation. Due to the high lead, the required engine speed is noticeably reduced in comparison to the classic design, so that the engines run significantly smoother and quieter, thus significantly increasing the service life of the engines. Instead of the commercially available castings, anodized aluminum machined parts are used with the Linearis TE, which are significantly more robust with a low weight. The Linearis has been developed by practitioners. Long holes in the brackets allow easy assembly. The dry running spindle nut prevents dirt build-up so that large and expensive bellows designs are no longer required. Likewise, the regular greasing is avoided by the lubricant-free construction.

The design of the Linearis lift unit also follows the Atex guidelines, so that the combination of linear unit and zone 1 drive form a reliable unit.

Force

N

Travel time

mm/s