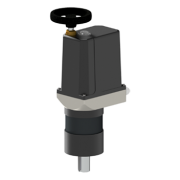

PICO – The Bridge between HCV- and Industrial Actuators

Aris Stellantriebe delivers with the “PICO” an actuator of extraordinary flexibility. Based on a Heating, Climate control and Ventilation technology actuator, the “PICO” offers many characteristics, which are required in industrial applications.

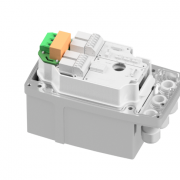

The company from Troisdorf (North Rhine-Westphalia) specializes in electric and pneumatic actuators. All Aris product series are subject to an ongoing evolutionary process, from which in part develop further enhancements and as well completely new series. Enhancements are often in details, making however altogether a tremendous difference. With the ambition to develop long-lasting, practical solutions, the actuator series PICO has been created offering consumers pricewise attractive devices without any loss in quality in comparison with industrial high-end actuators. The PICO production line is particularly interesting for OEM customers, as its modular design enables customized equipment. The PICO production line layout is for high volume series, thus making the economic benefit particularly significant.

By default, the PICO has protection class IP65 and assures, based on its ultrasonic-welded casing, minimal vulnerability against dirt and contamination. Its compact design facilitates its installation, even in tightly dimensioned plant layouts. For example, optional switches and potentiometers are inside in the protective casing as generally used in industrial applications, and not attached as additional body with separate cable connection. Settings and adjustments are made conveniently from outside. The possibility of an integrated spring reset is available as well. The actuator is ready for direct mounting on a great number of throttle valves, ball valves, and mixing valves. In contrast to other pricewise comparable products, Aris provides an own accessory program with an appropriate selection of components according to the requirements of the industry. From spacer mounting kits and positive locking reducers to clamping adapters, and modular enhancements offer customers multiple alternatives.

Performance as required

The company Aris Stellantriebe complemented sensibly its portfolio providing with actuators of up to 500Nm and the recent addition of the PICO product family appropriate solutions in both, the upper and lower performance range. After market launch, matching PICO variants for ball valve and throttle valve applications are available ex stock; later customized variants for OEM-customers are possible.